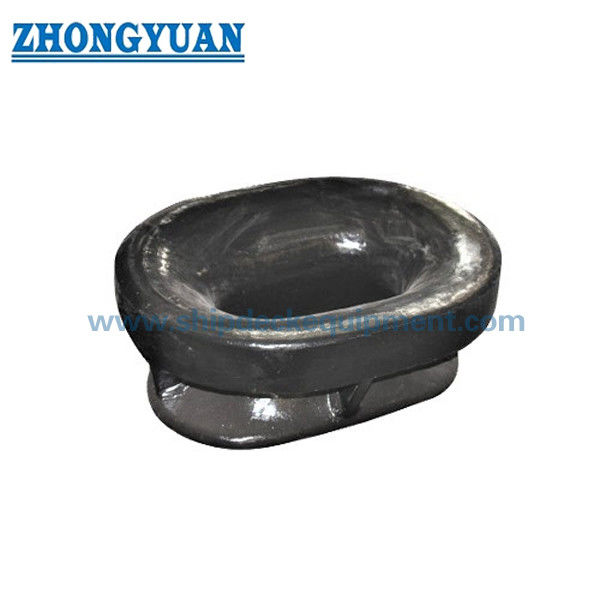

JIS F 2007-1976 Bulwark Mounted Mooring Chock (Type A, B) Ship Mooring Equipment

Product Details:

| Place of Origin: | China |

| Brand Name: | Zhongyuan |

| Certification: | CCS, NK, BV, ABS, DNV-GL, LR, KR, IRS, RS, RINA, Makers Test Certificate, Etc. |

| Model Number: | Standard and Customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | As per quotation |

| Packaging Details: | Pallet or Customized |

| Delivery Time: | As per offer |

| Payment Terms: | TT, L/C, Etc. |

| Supply Ability: | Satisfy clients needs |

|

Detail Information |

|||

| Type: | Type A, Type B | Materials: | Casting C-Mn Steel, Casting Stainless Steel, Also Can Supply Special Steel For Icebreaker |

|---|---|---|---|

| Technical Standard: | JIS F 2007-1976 | Weight: | 15.1 To 115kg; 17.5-45.5kg |

| Surface Treatment: | Sandblasting To S2.5 + One Layer Of Epoxy Shop Primer, Galvanized, Polished, Customized Surface Treatment Available. | Classification Certificates: | CCS, NK, BV, ABS, DNV-GL, LR, KR, IRS |

| Highlight: | Type A Mooring Chock,Type B Mooring Chock,Ship Mooring Equipment Mooring Chock |

||

Product Description

JIS F 2007-1976 Bulwark Mounted Mooring Chock (Type A, B) Ship Mooring Equipment

Description:

JIS F 2007-1976 Mooring Chock is one of the bulwark mounted chock, normal model from model 150 to model 500. Any question please feel free to get in touch with us. Look forward to hearing from you. Any question please feel free to get in touch with us. Looking forward to hear from you.

Main Technical Specification:

1. Type: type A, type B;

2. Materials: Casting C-Mn Steel, Casting Stainless Steel, also can supply special steel for icebreaker.

3. Technical Standard: JIS F 2007-1976

4. Weight:15.1 to 115kg; 17.5-45.5kg

5. Surface treatment: sandblasting to S2.5 + one layer of epoxy shop primer, Polished Stainless Steel, customized surface treatment available.

6. Classification Certificates:CCS, NK, BV, ABS, DNV-GL, LR, KR, IRS

Main Technical Parameter:

| Nominal size | L | L1 | L2 | H | H1 | H2 | B | C | R | R1 | R2 | R3 | T | Leg of weld | Calculated mass kg | |||||

| 150 | 150 | 300 | 270 | 110 | 260 | 202 | 129 | 40 | 55 | 130 | 115 | 65 | 12 | 4 | 5 | 15.l | ||||

| 200 | 200 | 368 | 334 | 150 | 318 | 250 | 143 | 42 | 75 | 159 | 142 | 72 | 12 | 4 | 5 | 20.5 | ||||

| 250 | 250 | 430 | 394 | 200 | 380 | 308 | 155 | 44 | 100 | 190 | 172 | 78 | 12 | 4 | 5 | 26.9 | ||||

| 300 | 300 | 500 | 460 | 250 | 450 | 372 | 169 | 52 | 125 | 225 | 205 | 85 | 15 | 4 | 6 | 42.7 | ||||

| 350 | 350 | 560 | 518 | 250 | 460 | 378 | 179 | 55 | 125 | 230 | 209 | 90 | 15 | 6 | 6 | 50.8 | ||||

| 400 | 400 | 632 | 586 | 250 | 482 | 394 | 195 | 60 | 125 | 241 | 218 | 98 | 18 | 6 | 7 | 76.3 | ||||

| 450 | 450 | 700 | 650 | 250 | 500 | 406 | 209 | 62 | 125 | 250 | 225 | 105 | 20 | 6 | 8 | 102 | ||||

| 500 | 500 | 760 | 708 | 250 | 510 | 412 | 219 | 65 | 125 | 255 | 229 | 110 | 20 | 6 | 8 | 115 | ||||

| Nominal size | Nominal dia. of applicable rope (Reference) | |||||||||||||||||||

| Mani-la rope | Wire rope | |||||||||||||||||||

| 150 | 40 | 16(6×12) | ||||||||||||||||||

| 200 | 45 | 18 (6×12) | ||||||||||||||||||

| 250 | 50 | 20 (6×l2) | ||||||||||||||||||

| 300 | 60 | 22.4 (6×12) | ||||||||||||||||||

| 350 | 70 | 24 (6×24) | ||||||||||||||||||

| 400 | 80 | 26 (6×24) | ||||||||||||||||||

| 450 | 85 | 30 (6×24) | ||||||||||||||||||

| 500 | 90 | 35.5 (6×24) | ||||||||||||||||||

| Nominal size | L | L1 | L2 | B | C | R3 | T | Leg of weld | Calculated mass kg | |

| 150 | 150 | 318 | 288 | 144 | 42 | 72 | 12 | 4 | 5 | 17.5 |

| 200 | 200 | 380 | 346 | 155 | 44 | 78 | 12 | 4 | 5 | 23.5 |

| 250 | 250 | 450 | 414 | 169 | 52 | 85 | 15 | 4 | 6 | 37.5 |

| 300 | 300 | 510 | 470 | 179 | 55 | 90 | 15 | 4 | 6 | 45.5 |

| Nominal size | Nominal dia. of applicable rope (Reference) | ||

| Mani-la rope | Wire rope | ||

| 150 | 45 | 18(6×12) | |

| 200 | 50 | 20 (6×12) | |

| 250 | 60 | 22.4(6×l2) | |

| 300 | 70 | 24 (6×24) | |

![]()

Drawing of JIS F 2007-1976 Type A

![]()

Drawing of JIS F 2007-1976 Type B

![]()

![]()