High Energy Absorption D Type Rubber Fender For Ship Marine Rubber Fender

Product Details:

| Place of Origin: | China |

| Brand Name: | Zhongyuan |

| Certification: | CCS, NK, BV, ABS, DNV-GL, LR, KR, IRS, RS, RINA, Makers Test Certificate, Etc. |

| Model Number: | Standard and Customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | As per quotation |

| Packaging Details: | Pallet or Customized |

| Delivery Time: | As per offer |

| Payment Terms: | TT, L/C, Etc. |

| Supply Ability: | Satisfy clients needs |

|

Detail Information |

|||

| Type: | DD, DC | Applicable To: | Frame Dock And Ship's Hull Installation |

|---|---|---|---|

| Certification: | CCS, BV, ABS And SGS | ||

| Highlight: | black d type rubber fender,dock d type rubber fender,ship rubber d fender |

||

Product Description

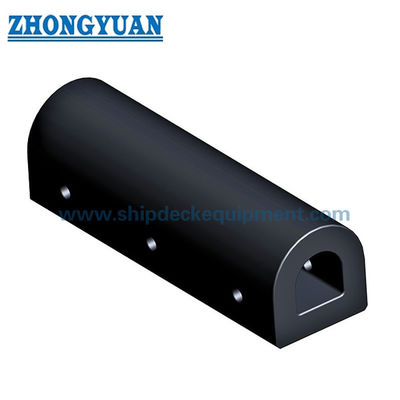

High Energy Absorption D Type Rubber Fender For Ship Marine Rubber Fender

Description:

D type rubber fenders are used in quay side, boat underwater part. Production process is fully automatic winding the overall molding vulcanization and mechanical vehicle processing groove process. The workmanship makes the rubber fender has good & long-life performance, utility, easily installation. Our Rubber Fenders are made of high abrasion resistance rubber with good resilience properties for required applications. These fenders are easy to install and dismantle.

Application:

Type: DD, DC

Applicable to frame dock and ship's hull installation.

CCS, BV, ABS and SGS certification.

Fender Type:

1, Cylindrical Type (Type Y) Rubber fender

2, D type Rubber Fender

3, GD type Rubber Fender

4, Super Arch type Rubber Fender

5, BF type Rubber Fender

6, Rubber Fender bonded with UHMW-PE pad

7, Super Cell Rubber Fender

8, Cone Type Rubber Fender

9, ME Type Rubber Fender

10, ST Type Rubber Fender

11, Tug Fender

12, W type Rubber Fender

13, XT Rubber Fender

14, Roll Rubber Fender

15, Pneumatic (Yokohama) Rubber Fender

16, Foam Filled Rubber Fender

17, Keyhole Rubber Fender

18, Unit Element Fenders

19, Rubber Ladder Fender

20, Square Rubber Fender

21 Type Wing Rubber Fender

22, Air Bag

Main Technical Specifications:

1) The reaction force is moderate; the absorbing energy is higher than the cylinder type.

2) Easy to install.

3) Due to the small size of the bottom width, it is generally suitable for frame dock and ship's hull installation.

| Type | H | B | I | Holes | Q | C | h | D | d |

| D125 X125 X 1000 | 125 | 125 | 1000 | 3 | 300-400 | 100-150 | 32.5 | 45 | 20 |

| D150X150X1000 | 150 | 150 | 1000 | 3 | 300-400 | 100-150 | 37.5 | 60 | 25 |

| D200X1S0X1000 | 150 | 200 | 1000 | 3 | 300-400 | 100-150 | 38 | 60 | 25 |

| D200X200X 1000 | 200 | 200 | 1000 | 3 | 300-400 | 100-150 | 50 | 60 | 30 |

| D200X250X 1000 | 250 | 200 | 1000 | 3 | 300-400 | 100-150 | 50 | 60 | 30 |

| D250X250X 1000 | 250 | 250 | 1000 | 3 | 300-400 | 100-150 | 62.5 | 65 | 32 |

| D300X300x1000 | 300 | 300 | 1000 | 3 | 300-400 | 100-150 | 75 | 6S | 35 |

| D350X350X1000 | 350 | 300 | 1000 | 3 | 300-400 | 100-150 | 87.5 | 80 | 38 |

| D380X380X1000 | 380 | 380 | 1000 | 3 | 300-400 | 100-150 | 95 | 80 | 40 |

| D400x400x1000 | 400 | 400 | 1000 | 3 | 300-400 | 100-150 | 100 | 80 | 40 |

| D500x500x1000 | 500 | 500 | 1000 | 3 | 300-400 | 100-150 | 125 | 90 | 45 |

| TYPES | M | H | B | L | Holes | Q | C | h | D | d | Remarks |

| DC150X1000 | 75 | 150 | ISO | 1000 | 3 | 300-400 | 100~150 | 37.5 | 60 | 25 |

Fenders of other specification and size can be discussed w ith customers |

| DC200XI000 | 95 | 200 | 200 | 1000 | 3 | 300-400 | 100~150 | 50 | 60 | 30 | |

| DC250X1000 | 125 | 250 | 250 | 1000 | 3 | 300-400 | 100~150 | 62.5 | 65 | 32 | |

| DC300X1000 | 150 | 300 | 300 | 1000 | 3 | 300-400 | 100~150 | 75 | 65 | 35 | |

| DC350X1000 | 150 | 350 | 350 | 1000 | 3 | 300-400 | 100~150 | 87.5 | 80 | 38 | |

| DC400X1000 | 200 | 400 | 400 | 1000 | 3 | 300-400 | 100~150 | 100 | 80 | 40 | |

| DC500X1000 | 250 | 500 | 500 | 1000 | 3 | 300-400 | 100~150 | 125 | 90 | 45 |

![]()

Performance of DC type

Performance Curve

![]()

| TYPES | Performance | |||

| Design compressive deflection (%) |

Reaction Force (KN) |

Absorption Energy (KJ) |

Tolerance % |

|

| DC150X1000 | 40 | 82 | 1.9 | ±10 |

| DC200X1000 | 109 | 3.4 | ||

| DC250X1000 | 136 | 5.4 | ||

| DC300X1000 | 165 | 7.7 | ||

| DC350X1000 | 189 | 10.5 | ||

| DC400X1000 | 218 | 14 | ||

| DC500X1000 | 273 | 21.5 | ||

![]()

![]()